Metrics, from the Latin to measure, is a fairly modern term that is used to describe the processes that a business measures. Metrics as an umbrella term refers to all these measures, whereas a KPI is more specifically related to a strategic business goal and a specific process. While KPIs are always metrics, metrics are not necessarily KPIs. Metrics that are not KPIs are usually tactical in nature and utilized to address a short-term process break down.

These semantics help us to understand the types of information that should be chosen for departmental and corporate dashboards. KPIs are permanent fixtures on the dashboard and while the targets may change, the definitions and structure of the KPI remain stable. This is done to ensure year over year baselining and continuous improvement. Metrics that are not KPIs will often be added to a dashboard for short term monitoring of pain points and corrective actions.

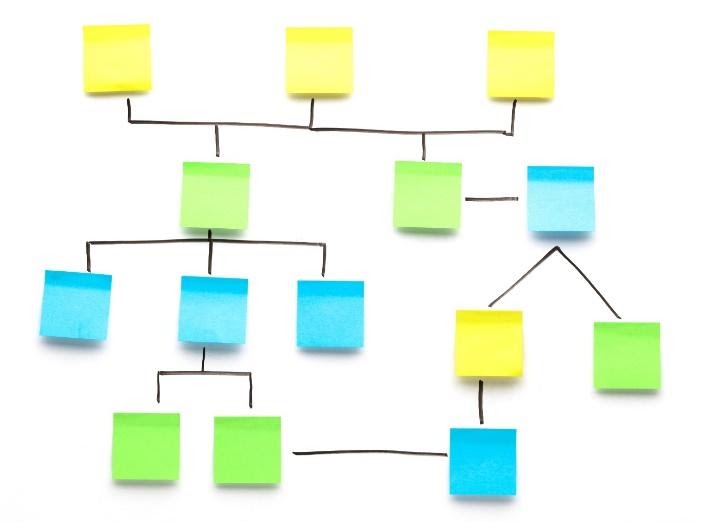

When selecting or creating KPIs they need to be linked to a strategic business goal. This is to say that the purpose is to push business growth, improvement and development. KPIs should be S.M.A.R.T.

SMART is a mnemonic device. A KPI is Specific in its scope of improvement. A KPI should be Measurable in that it can be quantified or valuated. A KPIs target is Assignable and Achievable. A KPI measure should be Repeatable, in other words the measurement should require little effort to take in relation to the effort of the process it is measuring. Finally, a KPI needs to have a Target and be related to Time, i.e. it needs to specify when it can be achieved.

Improve yearly sales is a goal. Improve total YTD sales revenue of the footwear line by 5% in Fiscal Year 2020 is a SMART KPI. This KPI might be linked to a Strategic Business Goal such as increasing Profitability by 2.5% by 2025.

Another way to think about selecting KPIs is to ask a series of questions about the business. The first concept is to get to the Core Business of the company. KPIs should focus on the Core Business first.

What are we in the business of? What are we good at?

Next is to hone in on the key drivers of that Core Business. The processes that are required to a) deliver on the core business and b) collect income from the core business.

Which processes are key to the doing It right? What do the customers see/think/experience? What do the shareholders see/think/experience? What do the employees see/think/experience?

Once you have narrowed this list to the most important items and know what to measure, we need to decide how to measure.

There are tons of great resources on the web for Six Sigma and Lean process theory. Core to all those methodologies is one tenant. If a process is under control and the inputs to the process are measured for defects, then the output results will be stable. If I am baking a cake and I use the same quality ingredients, in the same amounts every time. Apply the same heat for the same length of time. The quality of my cake will be the same every time I bake it.

This is the crux of KPI theory.

The process error or error free theory is about identifying the success of a process holistically. In this theory we are judging the success of the process not any individual step but by experiencing it the way our customer, internal or external, would.

Take the example of a simple picking, packing and billing process. A series of items are picked, grouped together and then shipped to a customer. On completion of the shipment an invoice is generated for the items. Each step in the process is individually evaluated for errors and the total errors is subtracted from the total opportunities to arrive at an error free calculation and then divided by the total opportunities to arrive at a percent ratio.

(Total potential Errors – Actual Errors)/Total Potential Errors

For example, in the picking stage a line item could have the wrong part pulled or the wrong quantity pulled. So, each line has two possible errors. If one hundred and fifty lines are shipped that is a TPE of 300 2*150. If during a nights shipping 4 wrong quantities and 3 wrong parts were pulled, the error free ratio is 293/300 = (300-4-3)/300 = 97.66% error free.

This error free ratio is only looking at the Picking department. Let’s look at some numbers for the other stages as well.

While there is room for improvement none of these numbers by themselves seem terrible but using a little math theory, we can multiple these individual ratios together to see how the customer experience of this situation appears.

97.66% * 99.33% * 99.00% = 90.244%

The net effect of our process is that 1 in 10 of our interactions with customers resulted in customer dissatisfaction.

When talking about process improvements and KPIs it is important to remember the Law of Diminishing returns. We have covered the Pareto Principal before but as a recap.

The Pareto Principal was originally discovered in economics it has since been shown to apply throughout the natural and business worlds. The key concept is that roughly 20% of the root causes will result in 80% of the volume and vice versa. That means that focusing on the 1 or 2 most common errors will reduce the strain on a process in roughly 80% of the occurrences. It also means that getting closer to a perfect process requires more effort as the further down list of reasons one goes the less volume of issues are impacted.

This principal also relates to measuring KPIs. No company has the resources to measure everything or to review and monitor all those measures even if it could. Picking the vital few KPIs that gives the widest view with the earliest warning to things going wrong is key to our success. To go back to the cake example, worrying about being off a few grams on flour, salt or sugar would not be as critical as knowing that our oven was heating at 20 degrees less than we needed. In business we don’t want a flat cake.

This has been an introduction to metrics and KPIs selection. I plan to revisit the topic again in a future article but in the meantime, if you have questions or advice on implementing KPIs, please don’t suffer in silence, myself and the CS3 Technology team are here to assist.

Image by Goumbik from Pixabay.